We manufacture and specify cable management solutions every day, and from that experience we treat wrap-around cable sleeves as a practical middle ground between permanent sleeving (closed braided sleeves, extruded tubing) and field repairs (heat-shrink). They are open along their length (split or side-entry), which permits installation over existing harnesses without disassembly. Typical variants offer self-closing braid, hook-and-loop strips, zippers, or pressure-sensitive adhesive. When selected correctly they protect against abrasion, contain EMI shielding layers if required, and simplify maintenance over the product life.

What is a wrap-around cable sleeve

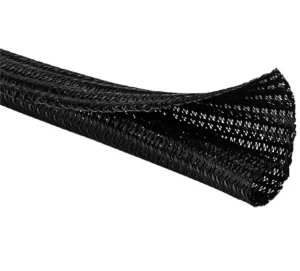

A wrap-around sleeve is a flexible protective covering that is open along one axis so it can be wrapped around cables, hoses or wire bundles. The opening may be a braided self-closing overlap, a zipper, hook-and-loop fastener, or adhesive tape. Many designs are braided and expandable to accommodate a range of bundle diameters; others are molded or laminated for special performance. The side-entry configuration is common in assembly, since it removes the need to disconnect connectors.

Main variants and how they differ

We classify sleeves by construction and closure method:

-

Split braided / side-entry woven — semi-rigid braid with overlapping strands that close around the bundle. Good for variable diameters and general protection.

-

Hook-and-loop (Velcro) wrap — textile sleeve with a hook/loop edge for reuse and rapid serviceability. Best for office, server racks, and light industrial use.

-

Zippered sleeves — textile or molded sleeves with a zipper closure; useful when structured access control is needed (e.g., cable trays where repeated access occurs).

-

Adhesive or heat-activated wrap-around patches — used for insulation repair and high-voltage jacket restoration; these are sometimes cross-linked polyolefin or specialty tapes that provide sealing.

-

Split extruded tubing / wire loom — molded polymer with a longitudinal split and fixed shape; highly abrasion resistant for chassis or conduit runs.

Each family trades off installation speed, re-entry, expandability, and environmental resistance.

Materials and construction details

Material choice controls temperature limits, chemical resistance, mechanical toughness and flammability behavior.

-

Polyester (PET) braided sleeves — widely used for expandability and general abrasion protection. They offer good cut and wear resistance and can be manufactured with a self-closing weave.

-

Nylon (polyamide 6/6) braided sleeves — tougher under repeated flexing and resistant to many solvents and automotive fluids; common for harnesses exposed to movement.

-

High-temperature glass or aramid (meta-aramid) braids — used for thermal protection near exhausts or welding zones; these resist sparks and molten splatter.

-

Polyethylene / polypropylene split looms — economical and stiff; used in routing inside enclosures and for low-cost protection.

-

Cross-linked polyolefin repair wraps (heat shrink style, but wrap-on) — provide electrical insulation and environmental sealing for splices; 3M offers such products for medium-voltage jacket repairs.

Construction notes: braided sleeves can be produced with tracers for identification, with fluoropolymer coatings for chemical resistance, or with conductive shields embedded for EMI control. When a sleeve self-closes, manufacturers often specify an overlap percentage that determines how much expansion is possible without exposing wires.

Performance characteristics and ratings

When specifying, we focus on a handful of measurable attributes:

-

Operating temperature: depends on material. Typical PET/nylon sleeves operate comfortably between roughly -40°C and +125°C; high-temp aramid or glass styles extend beyond +250°C in short bursts. Zippertubing and other engineered wraps specify precise ranges for each product line.

-

Flammability / smoke: many braided and polyethylene sleeves carry UL94 ratings (V-2, V-1) or halogen-free formulations for low smoke/toxic gas. For appliance or building use select halogen-free, low-smoke materials when codes require.

-

Abrasion and cut resistance: braid density, filament type and weave determine resistance. Monofilament nylon or PET with tighter weaves increases mechanical protection.

-

Chemical resistance: polypropylene and polyethylene resist many acids and bases; nylon tolerates common automotive fluids but can absorb moisture causing minor dimensional changes. For fuel and solvent exposure, choose chemically rated polymers or fluoropolymers.

-

Electrical insulation / voltage rating: most textile braided sleeves provide mechanical protection but are not intended as primary electrical insulation. Use wrap-on polyolefin repair sleeves or heat-shrink where dielectric protection is required.

Citing test data and spec sheets for the specific SKU is essential; published operating temperatures and UL listings vary significantly across suppliers.

Typical sizes, overlap and expandability

Wrap-around sleeves are sold by internal diameter (when closed) and by braid expansion ratio. Common ranges:

-

Small computer/AV runs: 6–12 mm closed diameters, expanding to ~20–25 mm.

-

Automotive harnesses: 10 mm to 50+ mm closed diameters; expandable braided sleeves commonly state an expansion factor (e.g., 2×–3×).

Manufacturers usually state the amount of overlap in split braided sleeves (commonly ~25% overlap) which affects how much expansion is available without exposing the bundle. That overlap also influences how well the sleeve self-closes under vibration.

Installation best practices

We advise field technicians and design engineers to follow a few simple steps for reliable installation:

-

Measure the bundle diameter under maximum expected load and with connectors in place. Add margin for future cable additions.

-

Select sleeve with appropriate expansion and closure type. For harnesses subject to frequent service choose hook-and-loop or zippered sleeves; for permanent retrofit, self-closing braided sleeves are faster.

-

Secure ends: use heat-shrink collars, adhesive tape, or banding to prevent fraying and to keep contaminants out. For halogen-free or high-temp applications use compatible end seals.

-

Allow slack and bend radii: avoid compressing cables by over-tight sleeving. Sleeves should not force cables into smaller radii than the cable manufacturer allows.

-

Labeling: add identification tags or tracers before installation if long runs will be inaccessible.

For harnesses exposed to heat or welding splatter, combine a thermal wrap near the source and a braided sleeve for strain and abrasion protection further down the run.

Maintenance, re-entry and serviceability

One of the strong advantages of wrap-around sleeves is re-entry:

-

Zipper and hook-and-loop sleeves enable repeated access without cutting. This reduces downtime for server rooms and test rigs.

-

Self-closing braided sleeves provide quick installation but can be difficult to re-open without cutting; however, they can be slid along a bundle to expose connectors if there is slack.

Routine inspection should check for wear points, fraying, chemical attack, or loss of flame retardancy. Replace sleeves showing significant degradation. For fixed runs in safety-critical applications (e.g., aircraft, railway) follow the OEM maintenance intervals and replacement criteria.

Common applications and industry examples

We use wrap-around sleeves across many sectors:

-

Automotive and heavy vehicles: harness protection, abrasion points, trunk and engine bay bundling. Nylon and high-temp variants are common.

-

Industrial machinery: hose bundling, drag chains, factory floors—often combining sleeve and conduit for mechanical protection.

-

Aerospace and rail: specified aramid or glass braided sleeves for thermal and fire performance, plus protective coatings where needed.

-

Office and AV installations: zipper or hook-and-loop sleeves for desk and rack cable management; aesthetic covers for visible runs.

-

Field repairs and energy utilities: wrap-on repair sleeves for jacket restoration and joint sealing in medium-voltage applications.

When writing specifications, we match the sleeve family to the worst-case environment rather than the average condition.

How wrap-around sleeves compare to alternatives

We compare common protections using a practical table.

| Solution | Re-entry | Expandability | Mechanical protection | Thermal resistance | Typical use |

|---|---|---|---|---|---|

| Wrap-around braided sleeve | Moderate (cut for braid; zipper/Velcro = high) | High (braid expands) | Good | Moderate | Harness retrofit, variable bundles. |

| Closed braided sleeve | Low (must thread on) | Low–moderate | Excellent | Moderate–high | New harnesses, OEM looms. |

| Split extruded tubing (wire loom) | High | Low | High (rigid) | Low–moderate | Chassis routing, rigid protection. |

| Heat-shrink tubing | Low | None | Excellent (after shrink) | High (depending on material) | Electrical insulation, strain relief. |

| Wrap-on polyolefin repair sleeve | Low–moderate | Low | Good | High | Jacket repair, insulation restoration. |

This comparison helps us pick a solution that balances serviceability with robustness.

Selection checklist for engineers and purchasers

When we specify or procure, we tick the following boxes:

-

Confirm maximum and minimum operating temperature and any transient peaks.

-

Check flammability/UL listing and halogen content if required for the environment.

-

Measure bundle diameter with connectors and add margin for growth.

-

Decide closure: permanent vs. serviceable.

-

Inspect chemical and fluid compatibility with expected exposures.

-

Order samples for hands-on fit testing; field tolerance for texture, compression and friction is best validated physically.

Buying by the meter or reel is typical; for large programs request manufacturer test certificates and nominal batch samples.

Installation tools and end-treatment

We use a modest toolkit for clean installations:

-

Sharp scissors or blade for clean cuts; treat braid ends with heat or adhesive to prevent fray.

-

Heat-shrink end seals and adhesive collars for environmental sealing.

-

Cable ties, low-profile clamps, and grommets for strain relief at bulkhead penetrations.

For braided sleeves, tape the open end temporarily to help slide the braid onto the bundle; for stiff split looms, a small wedge or prying tool helps open the slit for placement.

Environmental and compliance considerations

Environmental rules and workplace safety may restrict certain chemistries:

-

Halogen-free requirement: public buildings and some OEM contracts require halogen-free materials to limit toxic gas during fire. Choose halogen-free ratings where required. tnb.ca

-

RoHS / REACH: for electronics and EU markets, check polymer additives and flame retardants for compliance.

-

Automotive OEM standards: many vehicle makers specify heat, fluid, and abrasion performance plus traceability and batch documentation. Request compliance statements from suppliers when needed.

Typical failures and troubleshooting

Common failure modes we observe and fixes:

-

Abrasion at high-movement points: use higher-density braid, add outer abrasion sleeves, or relocate the harness.

-

Fraying at cuts: add heat-seal, tape, or rubber grommet; specify cut-resistant filament.

-

Chemical degradation: replace with chemically resistant polymer or fluoropolymer.

-

Loss of closure under vibration (zipper or hook failure): use overlapping braided sleeve or secondary retention such as stainless band clamps.

Root cause analysis typically begins with environmental mapping: temperature, movement cycles, contaminants, and mechanical loads.

Procurement and supply chain notes

We recommend the following purchasing practices:

-

Specify performance, not only material name. Say “braided PET, 25% overlap, 12–50 mm expansion, UL94 V-2” rather than only “braided sleeve.” Suppliers may offer variants that meet the performance but differ materially.

-

Sample before volume buy: verify fit and abrasion behavior.

-

Request certifications: UL/CSA listings, test reports for temperature and flammability when safety standards apply.

For complex projects, include an engineering change clearance for any sleeve type that will be retrofitted to an existing fleet or product line.

Practical design examples

We often use these patterns:

-

Engine harness near exhaust: layered protection — a short aramid wrap for thermal insult, then a longer braided nylon sleeve for abrasion and bundling.

-

Server rack bundle management: hook-and-loop wrap-on sleeves with color tracers for quick cable tracing and re-entry.

-

Field cable jacket repair: 3M wrap-on polyolefin sleeve to re-establish dielectric and moisture barrier on damaged cable jackets.

These choices reflect trade-offs among cost, longevity, and access.

Quick reference table — common options and typical spec ranges

| Product family | Typical materials | Nominal closed ID range | Expansion behavior | Typical temp range (°C) |

|---|---|---|---|---|

| Wrap-around braided (self-close) | PET, Nylon | 6 mm – 50+ mm | 1.5× – 3× | -40 to +125 |

| Zippered textile sleeve | Polyester, Nylon | 10 mm – 60 mm | Low | -20 to +100 |

| Hook-and-loop wrap | Woven polyester | 10 mm – 100 mm | Limited | -20 to +100 |

| Split extruded loom | Polyethylene / PP | 8 mm – 50 mm | Minimal | -40 to +85 |

| High temp aramid/glass braid | Meta-aramid, Glass | 6 mm – 40 mm | Low–moderate | up to +250 (short) |

| Wrap-on repair sleeve | Cross-linked polyolefin | Custom | None after cure | -40 to +125 (varies) |

Note: exact temperature and expansion figures are manufacturer dependent. Confirm with the chosen SKU.

Frequently asked questions

Q1: Can wrap-around braided sleeves be used to stop electrical shorts?

A1: Braided textile sleeves provide mechanical protection and limited dielectric separation but are not intended as primary electrical insulation for live conductors. For dielectric repair or voltage insulating needs use heat-shrink or wrap-on insulating sleeves that are specifically rated for the voltage.

Q2: How do I prevent fraying of braided sleeve edges?

A2: Seal cut edges using heat (for thermoplastic filaments), adhesive wrap, or end-fittings. Some sleeves accept heat-shrink collars that provide both mechanical termination and environmental sealing.

Q3: Which sleeve is best for engine compartments exposed to oils and fuels?

A3: Choose nylon or fluoropolymer-coated braided sleeves with proven resistance to hydrocarbons, and where temperatures are high add a thermal layer (aramid or glass) near the source. Always verify the supplier’s chemical compatibility data.

Q4: Are wrap-around sleeves reusable?

A4: Yes — zipper and hook-and-loop styles are explicitly reusable and designed for repeated re-entry. Self-closing braided sleeves are reusable in the sense that they can be re-positioned, but repeated cutting or heavy abrasion will reduce service life.

Q5: What environmental certifications should I request?

A5: Ask for UL/CSA listings for flammability, halogen-free declarations where required, RoHS/REACH statements for chemical compliance, and manufacturer test reports for tensile, abrasion and temperature cycling when the application is safety-critical.