A properly specified steel power pole is a purpose-built structural element engineered to meet defined wind, ice, electrical and mechanical loads while delivering long service life through appropriate material selection, fabrication, protective coating, foundation design and quality control. The core requirements combine structural design criteria from civil and electrical standards, ASTM-grade steel and welds, controlled geometry and hole patterns, and corrosion protection systems that together produce predictable performance and low lifetime cost.

Steel poles for power delivery perform two linked roles: they provide a durable structural support for conductors and equipment, and they form part of the energized system that must satisfy electrical clearances, grounding and access requirements. Typical applications include distribution lines (up to medium voltage), transmission monopoles and H-frames, street and area lighting and telecom mounts. A specification must therefore describe scope, required standards, mechanical class, electrical attachments, surface finish, testing, documentation and delivery conditions.

Applicable codes and performance criteria

A robust specification lists the governing standards and references them where precise limits or test methods are needed. For steel power poles, common references include the American Society of Civil Engineers design guides, the National Electric Safety Code for minimum electrical clearances, ASTM standards for steel grades and coatings, AWS documents for welding, and recognized ANSI pole-class criteria that provide comparative loading metrics. Utilities frequently incorporate these references into contract language and adapt wind and ice loads to local jurisdictional requirements.

Key performance requirements to state explicitly:

-

Design wind speed and exposure category

-

Ice thickness and radial ice load, if applicable

-

Electrical configuration: phase spacing, neutral, shield wires, crossarms, attachments

-

Ultimate moment capacity at a specified distance from the pole top or at the point-of-fixity

-

Fatigue and vibration considerations for long spans or tangent structures

Note on pole classification: many manufacturers and utilities map steel pole capacity to ANSI O5.1 or equivalent wood pole classes using a tip-load/moment approach, allowing direct substitution in plans that assume a wood pole class.

Materials, metallurgy and fabrication methods

Material selection determines strength, weldability and corrosion behavior. Common choices include hot-rolled structural steels produced to ASTM specifications for structural tubing or plate. Typical provisions cover:

-

Base steel: low-alloy, high-strength structural grades that meet specified yield and tensile properties.

-

Tube or tapered shell fabrication: seamless or welded tubular sections are formed, tapered and joined by sleeve, flange or swage methods. Where joined, overlap lengths and weld details are dimensioned to maintain section capacity.

-

Fasteners and hardware: specify bolt grades (A325, A354, A490, or equivalents), nuts, washers and anti-rotation devices. Use lock nuts or prevailing torque devices for vibration-prone applications.

-

Welding: require AWS-qualified procedures and welders. Include preheat, filler metal classification and post-weld inspection criteria such as visual, magnetic particle or ultrasonic testing for critical welds.

Manufacturing tolerances and concentricity are important because pole geometry controls buckling resistance and uplift behavior. The specification should define acceptable dimensional tolerances, hole location tolerance and coating continuity across joints.

Load cases, classification and design parameters

Engineers design poles against multiple limit states. The specification must define load combinations and required safety factors. Typical load cases include:

-

Dead loads: self-weight of pole, brackets and permanent attachments.

-

Live loads: conductor weight, insulator assemblies and maintenance loads.

-

Wind loads: on pole and mounted equipment; use local code wind speed and exposure.

-

Ice loads: radial or chordal ice accretion multiplied by wind pressure.

-

Short-circuit and electromagnetic loads: for distribution structures supporting fused equipment.

-

Impact or vehicular collision loads for roadside installations.

Two numeric design metrics are often specified and used by purchasers to compare manufacturers:

-

Tip load and equivalent ground-line moment: a horizontal force placed at a fixed distance from the top (commonly 2 ft) that produces the minimum required moment capacity above a defined point-of-fixity. This method aligns with ANSI O5.1 classification practice.

-

Ultimate moment capacity at a fixed location: often reported at 5 ft from the top or at the point-of-fixity. RUS and utility documents commonly provide tables that map pole classes to minimum moment capacities and horizontal tip loads.

Designers must specify whether the pole will be analyzed for bending only or for combined axial and bending loads. For tall monopoles and transmission structures, base moment capacity, buckling analysis and foundation design assumptions must be included in the contract.

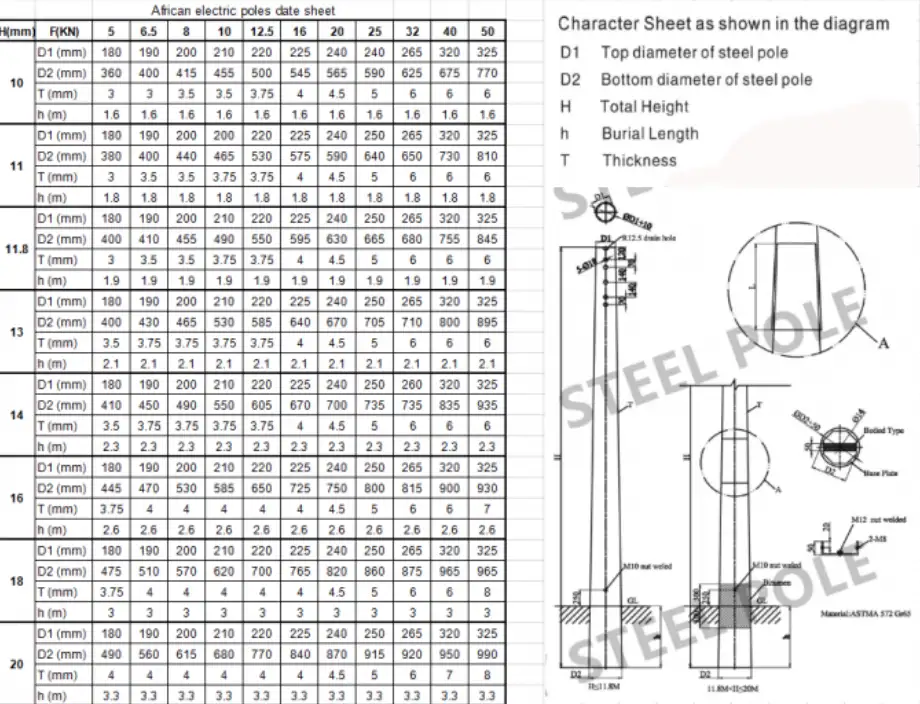

Typical geometries, dimensions and quick reference table

Steel poles are offered in tapered round, tapered multi-sided (octagonal) and straight smooth-wall sections. Sizes vary with height and load class. Below is a concise reference table presenting representative outer diameters and wall thicknesses for common distribution and transmission pole heights. Use it as a starting point; final dimensions must be verified by structural calculations tailored to the specified loads.

| Pole Type | Nominal Height (ft / m) | Typical Top OD (mm / in) | Typical Base OD (mm / in) | Typical Wall Thickness (mm / in) | Common Use |

|---|---|---|---|---|---|

| Tapered round, distribution | 20–40 ft (6–12 m) | 60–90 mm (2.4–3.5 in) | 90–180 mm (3.5–7.0 in) | 2.3–4.0 mm (0.09–0.16 in) | Low-voltage overhead, street lighting |

| Tapered round, medium distribution | 40–70 ft (12–21 m) | 90–140 mm (3.5–5.5 in) | 180–305 mm (7.0–12.0 in) | 3.5–6.4 mm (0.14–0.25 in) | Distribution lines, small transformers |

| Tapered octagonal, heavy distribution | 55–95 ft (17–29 m) | 100–160 mm (4–6.3 in) | 250–400 mm (9.8–15.7 in) | 4.0–8.0 mm (0.16–0.31 in) | Heavier distribution and light transmission |

| Transmission monopole | 60–150 ft (18–46 m) | 150–300 mm (6–12 in) | 400–900 mm (15.7–35.4 in) | 6.4–16 mm (0.25–0.63 in) | High-voltage single pole spans |

| H-frame (steel) | Varies | Custom | Custom | 6.4–19 mm (0.25–0.75 in) | Two-pole frames supporting heavy transmission |

This table provides approximate ranges. Manufacturers typically publish load charts that map pole geometry to ANSI or utility class numbers, enabling selection by required tip load or moment capacity.

Protective systems and corrosion control

Long service life depends on an engineered coating or metallurgical barrier. Common protective systems include:

-

Hot-dip galvanizing applied after fabrication to AASHTO/ASTM thickness requirements. This method provides a metallurgical zinc layer that bonds to steel and yields uniform coverage, including edges and welds where properly detailed. Specify minimum coating thickness measured by weight per area or microns.

-

Primer and paint systems for aesthetic or extra protection in aggressive coastal or industrial environments. When paint systems are used, require surface preparation to specified cleanliness followed by specified primer and topcoat films.

-

Cathodic systems or sacrificial anodes are occasionally used in buried bases or caisson installations.

-

Sealing of joints and end caps: poles should be sealed at the top and at fabrication joints to prevent water ingress, which can accelerate corrosion from inside-out.

Specification items to include:

-

Coating spec references and acceptance criteria.

-

Repair procedures for field-damaged coating areas.

-

Weld area treatment to ensure continuity of the protective layer.

A hot-dip galvanized finish is widely used for distribution and transmission poles because it combines economy, toughness and long-term performance.

Foundations, anchoring and installation notes

A structural specification must coordinate with geotechnical and foundation design. Common foundation types are embedded pole, concrete caisson, and bolted flange on cast-in-place footing. Key elements to address:

-

Embedment depth: typically a function of pole height and local soil; design documents often use point-of-fixity rules (e.g., 7% of pole length from base for some conversions) when matching wood equivalent classes. Confirm embedment and backfill compaction requirements.

-

Caisson and base plate: define base plate size, bolt circle, anchor bolt pattern, and hole tolerances. Provide anchor-bolt templates with permissible oversize to allow alignment.

-

Grouting and drainage: specify non-shrink grout between base plate and foundation and provide drainage to avoid water pooling around base or inside caisson.

-

Lifting and handling: provide recommended rigging points and maximum lift locations to protect structural sections; indicate whether poles ship in multi-piece sections requiring field splicing.

Include an installation appendix describing torque values for anchor bolts, sequence of assembly for multi-piece poles, grounding conductor attachment location and bonding requirements.

Inspection, testing and quality assurance

A specification should establish minimum QA/QC. Typical items include:

-

Mill test reports for steel chemistry and mechanical test results.

-

Dimensional inspection of supplied units against drawings.

-

Weld inspection: visual, dye-penetrant, magnetic particle or ultrasonic testing where required.

-

Coating inspection: measure thickness at multiple points, adhesion tests and holiday detection for coatings.

-

Load tests: some utility contracts require sample pole proof tests or full-scale or component testing; others rely on calculation and certified mill data.

-

Documentation: delivery should include drawings, certificates, test reports and a QA checklist.

A prescriptive acceptance protocol reduces ambiguity and speeds field acceptance.

Logistics, handling and lifecycle considerations

Steel poles are lighter and more uniform than wood, which simplifies shipping and reduces waste. Include these commercial clauses:

-

Packing and marking: detail end protection, stenciling of part numbers, handling orientation and shipping length limits.

-

Storage: recommend covered storage on timber skids, keep poles off soil and protect cut ends and coating.

-

Lifetime projections: provide corrosion rate assumptions for buried and above-ground portions and expected replacement intervals for coatings under specified environments.

-

Spare parts: specify supply of spare hardware kits, spare anchor bolts and bolt torque charts.

Manufacturers commonly supply pole load charts together with delivery so field engineers can confirm selection under as-built conditions.

Environmental, safety and compatibility issues

Address environmental exposures and safety integration:

-

Coastal or chemical exposure: require heavier coatings or duplex systems (galvanizing plus paint) for chloride-rich environments.

-

Bird and wildlife protection: specify bird guards, raptor perch discouragers or insulated covers for wildlife-prone routes.

-

Electromagnetic compatibility and grounding: ensure grounding details comply with electrical code; provide bonding points and lightning attachment zones.

-

Traffic safety: for roadside installations, define breakaway hardware if local regulation requires collision mitigation.

Safety during fabrication and erection should be enforced by the contractor and documented in method statements.

Technical annex — sample specification checklist

Use this checklist when preparing tender documents or purchase orders.

Part 1 — General

-

Scope and application defined (distribution, transmission, lighting)

-

Applicable standards and local codes listed

-

Delivery schedule and packaging requirements

Part 2 — Materials

-

Steel grade and mechanical properties specified

-

Welding procedure specification (WPS) and welder qualification required

-

Fastener grades specified (A325/A490 equivalents)

Part 3 — Fabrication

-

Section geometry, taper, length increments and joint details

-

Hole pattern, grounding pad location, and lifting points

-

Top sealing and cap detail

Part 4 — Surface treatment

-

Galvanizing standard and minimum mass per area (g/m²)

-

Paint system (if required) with dry film thickness

-

Repair procedures for coating damage

Part 5 — Testing and documentation

-

Mill test certificates and inspection reports required

-

Non-destructive testing requirements and acceptance criteria

-

Sample proof load test if required by purchaser

Part 6 — Installation and foundation

-

Anchor bolt pattern and tolerances

-

Embedment depth and backfill compaction requirements

-

Torquing and bonding instructions

FAQs

1) What standards should a steel power pole meet for distribution use?

Specify the relevant civil and electrical codes used in the project and require that the pole meet ASCE structural guidance, NESC minimum clearances and ASTM/AWS material and welding standards. Include ANSI-equivalent pole class mapping if you need one-to-one replacement with wood classes.

2) How is the pole class defined in practice?

Many utilities use a tip-load placed a set distance from the top to define class. That tip-load is translated into a required ultimate moment capacity at a specified location. This approach aligns with the pole-class comparators used in ANSI O5.1 and similar utility documents.

3) What coating is most common and why?

Hot-dip galvanizing after fabrication is common because it yields metallurgically bonded zinc coverage, good edge protection and durable corrosion resistance for above- and below-grade surfaces. Duplex systems add paint for enhanced aesthetics or extra protection in aggressive atmospheres.

4) When are multi-piece or flanged poles needed?

Poles taller than truckable lengths or those where transportation width is restricted are commonly supplied in multi-piece sections with flange joints or spliced sleeves. The specification should define joint overlap, bolt grade and torque, and sealing to prevent water ingress.

5) How should anchor bolts be specified?

Provide anchor bolt material grade, thread engagement, nut/washer type, template dimensions and allowable hole oversize. Include torque values and anchorage acceptance criteria for cast-in-place or post-installed anchors.

6) What test records must the supplier deliver?

Typically include mill test reports, welding procedure records, NDT reports, coating thickness readings and a dimensional inspection report. Add a signed certificate of compliance referencing the purchase order.

7) Can steel poles replace wood poles directly?

Yes, when the steel pole class matches or exceeds the wood pole class using equivalent tip-load or moment criteria. Ensure electrical clearances and attachment layouts are checked because hardware location and pole diameter differ.

8) What are common failure modes and mitigation?

Failures arise from corrosion, fatigue at welded joints, improper foundation design and impact. Mitigation includes robust coatings, fatigue-conscious detail design, correct embedment and foundation design, and protective measures at vehicle-exposed sites.